4 Ways Intelligent Automation Can Solve Supply Chain Labour Shortages

Amongst the many challenges facing the modern world in the wake of COVID-19, the labour shortage caused by the ever-evolving virus has been one of the most devastating.

At Australia’s largest supermarket chain Woolworths, 20% – 40% of the workforce has been absent from work due to falling ill with COVID-19 or being a close contact.

In the USA, more than 700,000 cases per day are reported on average, with upwards of five million Americans being quarantined in an attempt to slow the spread.

For the supply chain industry, the lack of workers is resulting in empty shelves, delayed shipments, and rising costs – this in the wake of a backlog of orders, and a shortage of equipment and supplies.

Consumers and companies are frustrated, and eager for solutions. In response, the supply chain industry has made a dramatic shift towards automation at an accelerated rate, to improve efficiencies and ensure shelves remain stocked.

Prior to COVID-19, companies were hesitant to digitise – it was perceived as too costly, and new technologies being seen as risky to adopt.

In the “new normal”, those same businesses grasp the importance of incorporating automation into their operating processes, with many investing a significant amount – in some cases 5-10% of revenues – into research and implementation of automation measures.

With supply chain technology focused on machine learning, artificial intelligence and robotics becoming more commonplace, costs have become more affordable. Businesses understand that without making critical investments in technology focused on streamlining and efficiency such as automation, their very survival may lie in the balance.

Humans will always be a critical part of the supply chain. After all, someone has to operate, implement and optimise the hardware, software and equipment to maintain operational efficiency of business operations. In the supply chain’s current state of being heavily reliant on manual labour, even the most easily implemented technology solution requires the appropriate talent to drive adoption.

But in the wake of the chaos caused by the lack of staff across manufacturing and distribution, intelligent automation (IA) is emerging at the forefront of creating the operational efficiencies needed to ensure such challenges will become a relic of the past.

There are many processes in the supply chain that are being automated using IA. It eliminates errors associated with manual input, speeds up data driven processes, and decreases inefficiencies and is available 24/7 across the whole supply chain. Freight management is time-critical, and because of its ability to work round the clock, IA technologies are achieving in record time what has taken the industry decades to attempt with mixed results – providing a systematic and scalable workflow much less reliant on manual labour.

Amongst the many problems being solved in the supply chain industry through AI automation, four stand out that, if implemented as a matter of industry best practice, may well serve as the key to preventing future supply chain disruption.

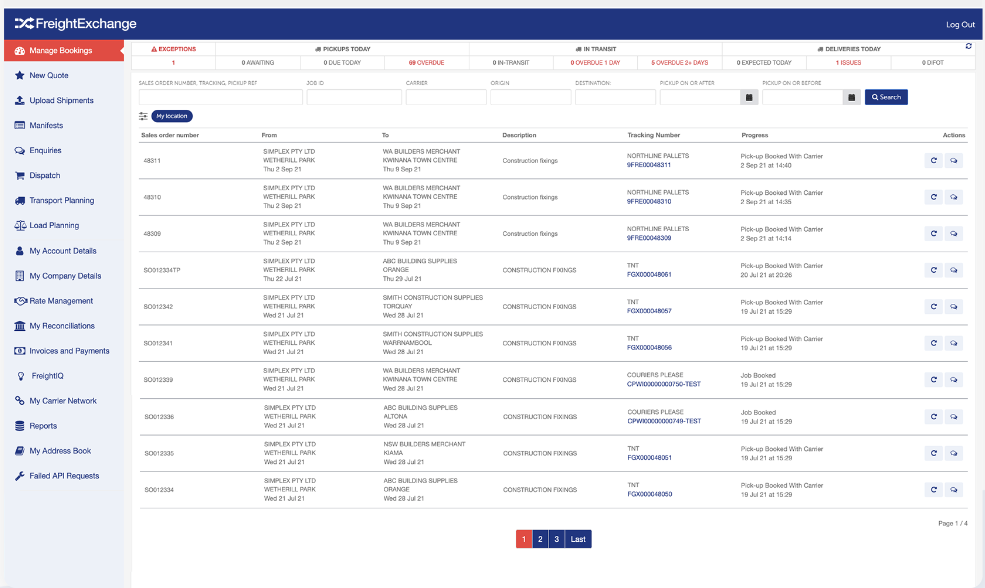

Frictionless Multi-carrier Matching

A multi-carrier shipping system is a tool that automates shipment decisions, enabling freight brokers to match a load with a variety of suitable transport options. This software does more than just aggregation; it allows for quote and service comparison, real-time freight tracking and delivery monitoring, minimising errors and reducing freight costs. With a few clicks, businesses can take what used to be an onerous, manual-labour-heavy task and instantly book the most appropriate carrier for their shipment.

Automated order integration with retail, ERP and CRM systems

One of the most time and labour-intensive aspects of shipping is the manual work required to enter shipments into a warehouse database for dispatch. Relying on manual processes to not only enter orders, but to update the databases related to e-commerce platforms, ERPs, and CRM systems, means huge margins for error, loss of data integrity and tedious work for already-overloaded employees struggling to keep up with demand.

Automated order integration is the consolidated, automatic entry of the order data pushed simultaneously into multiple systems. Orders from stores or ERP are pushed into the shipping queue automatically, without warehouse workers having to do any data entry other than reviewing their queue and dispatching orders when ready. The result is zero data double-ups, no manual decisions or errors, and a significant decrease in the reliance on a manual labour force.

Optimised Load Planning and Packaging Management

An area that has been noted for having the most potential for automation is the “picking and packing” process. Choosing goods to be shipped and matching them to the most appropriate packaging is optimised by platforms like FreightExchange which allow businesses to create and automatically allocate standard sets of packaging to shipments of various sizes. The labour costs and man-hours associated with choosing the most suitable packaging are greatly reduced with intelligent automation, resulting in better utilisation of volume, cheaper pricing and the added benefit of being better for the environment.

Automated Implementation of Backend Business Rules

The implementation of bespoke business rules plugged into the backend of warehouse inventory management software streamlines the shipping process through the establishment of optimal volumes via data tracking, reducing the need for manual oversight.

IA platforms like FreightExchange are automating the formerly time-and-labour intensive integration process with backend software, which in turn makes intelligent recommendations for how to use industry and business specific data for increased efficiency, no matter what industry you operate in.

With COVID-19 exposing glaring inefficiencies in the supply chain, the future of freight is well and truly being shaped by new technologies and agile tech companies able to solve problems faster than ever before. Technology will never entirely replace humans, but the intelligent automation trend means you can use less humans and get better results – all while giving the remaining labour-force the opportunity to focus on the business-critical work that matters most.

Are you an SME looking to save on time, money, and labour costs – all with a few clicks? Get in touch here for a free, obligation-free quote about how you can get started with the award-winning FreightExchange platform to ship your next load.

Next Opinion

Why 12x more Australian businesses are queuing for FreightExchange?

Our pipeline has grown 12x in the last 3 months alone (November 2021 – January 2022) I am Pushpinder, the […]

Read More